In today’s global economy, one thing is certain—uncertainty.

Tariffs, trade disputes, and shifting geopolitical dynamics have become a constant undercurrent in retail supply chains. What once were stable sourcing strategies are now vulnerable to sudden cost spikes, delays, and operational disruptions.

For retailers, these external shocks don’t just impact procurement—they cascade across inventory management, cash flow, and ultimately, profitability.

The Traditional Response: A Risky Balancing Act

When faced with looming tariffs or trade restrictions, many retailers fall into one of two traps:

- Over-ordering to “beat” the tariff clock, leading to excess inventory, tied-up capital, and higher markdown risk.

- Freezing orders out of caution, only to face stockouts, missed sales, and frustrated customers when demand returns.

Both reactions stem from a reliance on static planning models—where decisions are made months in advance, with little room to adapt once conditions change.

The Shift from Planning to Dynamic Execution

In a world where external factors can upend supply chains overnight, agility has become more valuable than accuracy. It’s no longer enough to plan well—you need to execute smarter, in real time.

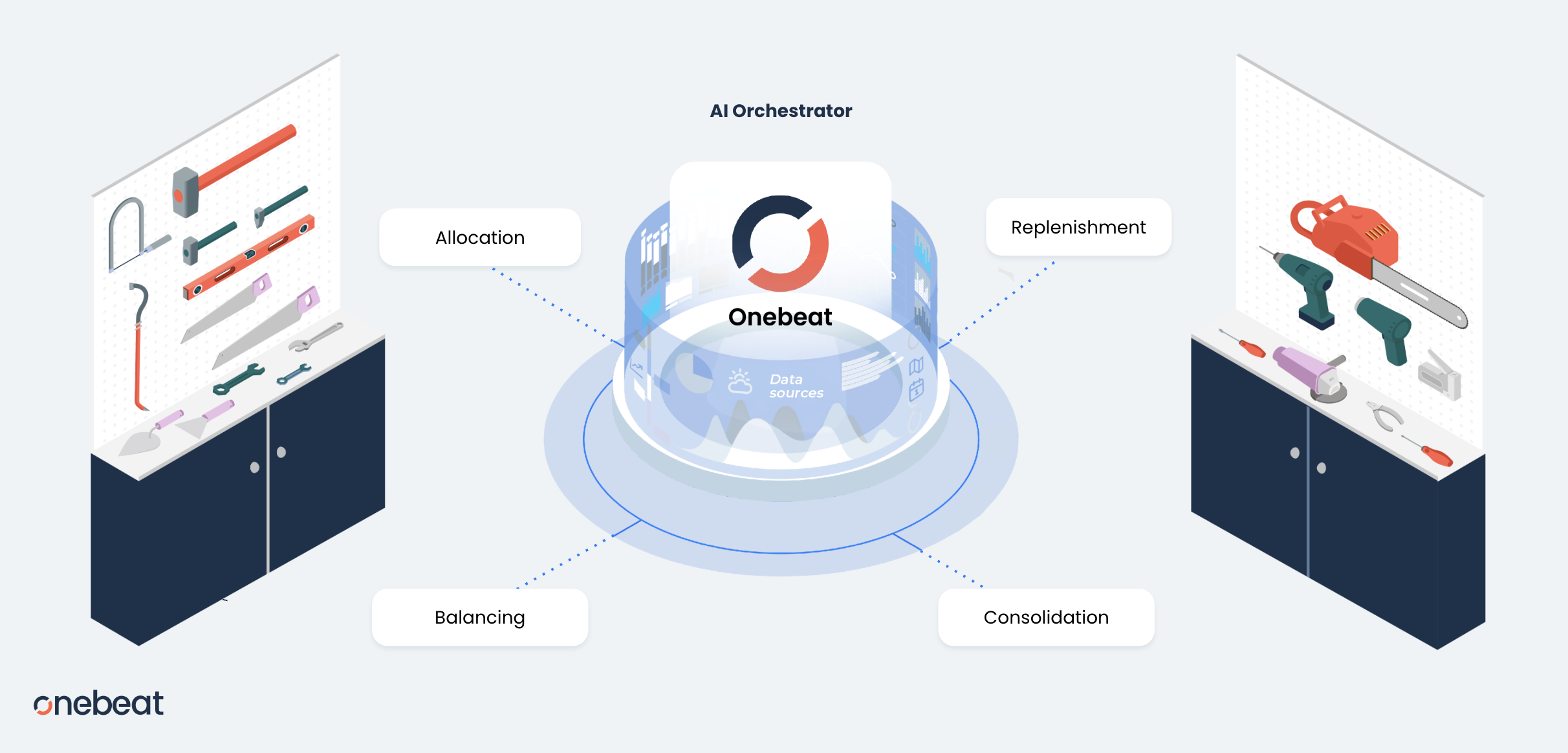

This means moving away from rigid forecast-driven inventory strategies and embracing approaches that allow for:

- Continuous adjustment based on live demand signals

- Smarter allocation and store transfers to maximize existing stock

- Faster reaction to disruptions without overcorrecting

Retailers who build this kind of flexibility into their operations can weather tariff shocks more effectively—by optimizing what’s already in their network, rather than relying on risky procurement bets.

Why Real-Time Inventory Agility Matters More Than Ever

Tariffs introduce both cost volatility and timing unpredictability. The ability to dynamically manage inventory flow—whether that’s reallocating stock, adjusting replenishments, or fine-tuning assortments at the store level—can mitigate many of these risks.

Key benefits of a more agile inventory strategy include:

- Minimizing exposure to supply chain delays by making better use of available stock

- Reducing the need for reactive, margin-eroding decisions like heavy discounting or emergency shipments

- Preserving cash flow by avoiding unnecessary inventory buildup

- Aligning inventory closer to real demand, even when upstream supply becomes unstable

From Uncertainty to Resilience

The reality is, global trade dynamics will continue to fluctuate. Retailers can’t control tariffs—but they can control how prepared they are to adapt.

Building resilience isn’t about trying to predict every disruption. It’s about creating operational systems that thrive amid unpredictability—where inventory isn’t just planned, but actively steered in response to real-world signals.

Those who prioritize real-time agility will find themselves less exposed, more flexible, and better positioned to turn external challenges into competitive advantages.

In times of volatility, speed and flexibility win over precision. As tariff pressures persist, the retailers who succeed will be those who rethink inventory management—not as a static plan, but as a dynamic, daily discipline.

Onebeat