Smart Replenishment

Stock the right product mix—and sell more at full price

Demand moves fast.

Make sure your inventory does too.

Onebeat helps you avoid shortages and overstocks by predicting demand and prioritizing where inventory goes next.

Demand moves fast.

Make sure your inventory does too.

Onebeat helps you avoid shortages and overstocks by predicting demand and prioritizing where inventory goes next.

Key benefits

Your stock should go where it sells—not where it sits.

Instead of sending an equal share of stock to every store, Onebeat uses AI to set dynamic inventory targets for every SKU and store, adapting to demand, delivery constraints, and store behavior.

So you can prioritize the right replenishment moves—without the guesswork or bloated buffers. And send each unit where it will sell the soonest.

That means higher sell-through, fewer markdowns, and lower holding costs.

ROI CALCULATOR

Onebeat ensures your bestsellers stay in stock—and slow movers don’t pile up.

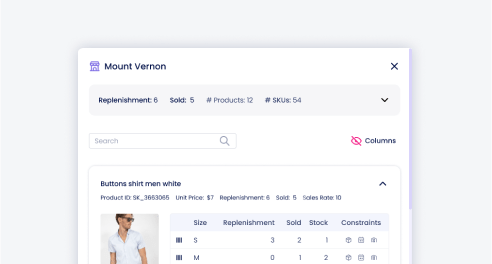

Automatic Policy Selection creates a unique inventory target for every SKU in every location based on demand history, delivery lead time, package constraints, and shipment capacity.

Use your inventory targets to move every SKU where it’s needed most, prioritizing stores with higher predicted sales for replenishment.

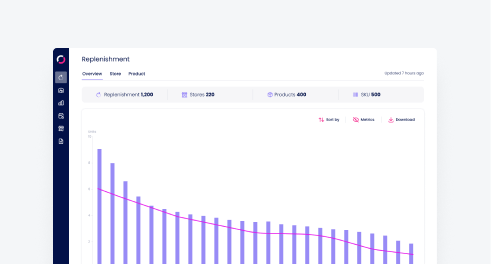

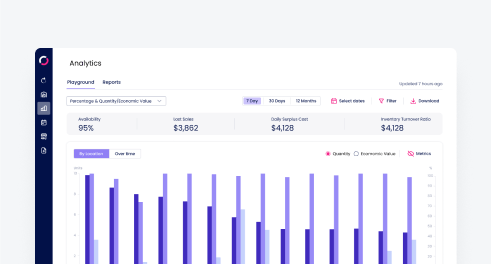

Use Onebeat’s detailed dashboards and SKU charts to track demand moment by moment—and watch your inventory targets adapt to the latest demand data.

OUR TECHNOLOGY

Unique inventory targets for every SKU in every location, based on AI-powered analysis of demand history, delivery lead time, package constraints, and shipment capacity.

Thousands of daily micro-adjustments based on demand data keep targets accurate — and help you seize every chance to sell at full price.

Built for the cloud—so you can implement fast, get inventory targets from anywhere, and start seeing ROI in just 120 days.

With Onebeat, the brand reacts to demand as it happens—cutting stockouts, avoiding excess, and improving customer satisfaction.

Why Onebeat

With volatile trends and fragmented demand, long-range planning alone can’t keep up.

Onebeat equips your team to act fast—prioritizing what to replenish, where, and when.

It’s how retail gets leaner, faster, and more profitable.

See how Onebeat can help you grow your bottom line by predicting when, where, and how much customers will buy—so you can stock smarter and sell more at full price.