Launching a new product is exciting, but striking the right balance between stocking too much inventory and too little is tricky. The key to getting it right? Precision. By understanding demand, segmenting your inventory strategically, and monitoring sales in real time, you can ensure every unit lands where it’s needed most. In this guide, we’ll walk you through actionable strategies to allocate stock intelligently during new product launches, helping you turn uncertainty into opportunity.

What You Will Learn

In this article, you will discover:

- How to forecast demand accurately for new product launches

- How to prioritize inventory by channel, region, and customer type

- Which data-driven methods improve stock allocation

- How brands use OneBeat to optimize inventory

How to Understand Your Demand?

Before you can allocate stock effectively, you need to understand how much of your new product customers actually want. Initial setup quantities always involve uncertainty, which leads many retailers to overallocate inventory to avoid missed sales. This approach sacrifices reactability and increases the risk of excess stock. AI-driven systems remove the need for these compromises by dynamically adjusting allocations as demand signals emerge.

Start by analyzing historical data:

Look at products with common attributes in your catalog, sales patterns, and seasonal trends. Even the small insights, such as which product variants tend to sell faster, or which regions historically outperform, can guide smarter allocation decisions.

Market research:

Customer surveys, social media trends, and competitor analysis can help you gauge interest and anticipate demand spikes. For example, if early buzz shows a particular product variant trending among your core audience, you should allocate a larger share of stock to meet the demand.

External factors:

External factors, such as holidays, promotions, or supply chain constraints, should be considered. A product launch during peak season may require a higher safety stock, while limited manufacturing capacity may force prioritization of high-value regions or customers. By combining data-driven insights with market intelligence, you’ll have a clearer picture of expected demand.

How to Segment Your Inventory Strategy?

Once you have a clear picture of demand, the next step is to decide where and how to allocate your stock. Not all products or customers are equal, and treating every region and channel the same may lead to wasted inventory and missed opportunities. To segment your inventory strategy, you should:

- Break it down by sales channels: Online stores and third-party marketplaces behave differently. For example, a product that flies off the shelves in a flagship store may move more slowly online. Therefore, stock should be allocated based on each channel’s likelihood to sell soonest to ensure you’re meeting customers where they shop.

- Geographical considerations can influence sales: Regional preferences, weather patterns, and local trends influence sales. For example, a cold-weather accessory may see high demand in northern regions, but less so in southern areas. You should prioritize regions with the highest expected sales and adjust shipments as early as sales data comes in.

- Segment by customer: Some brands benefit from prioritizing VIP customers or local buyers during product launches. Early access or pre-orders for high-value customers strengthen loyalty and help forecast wider demand.

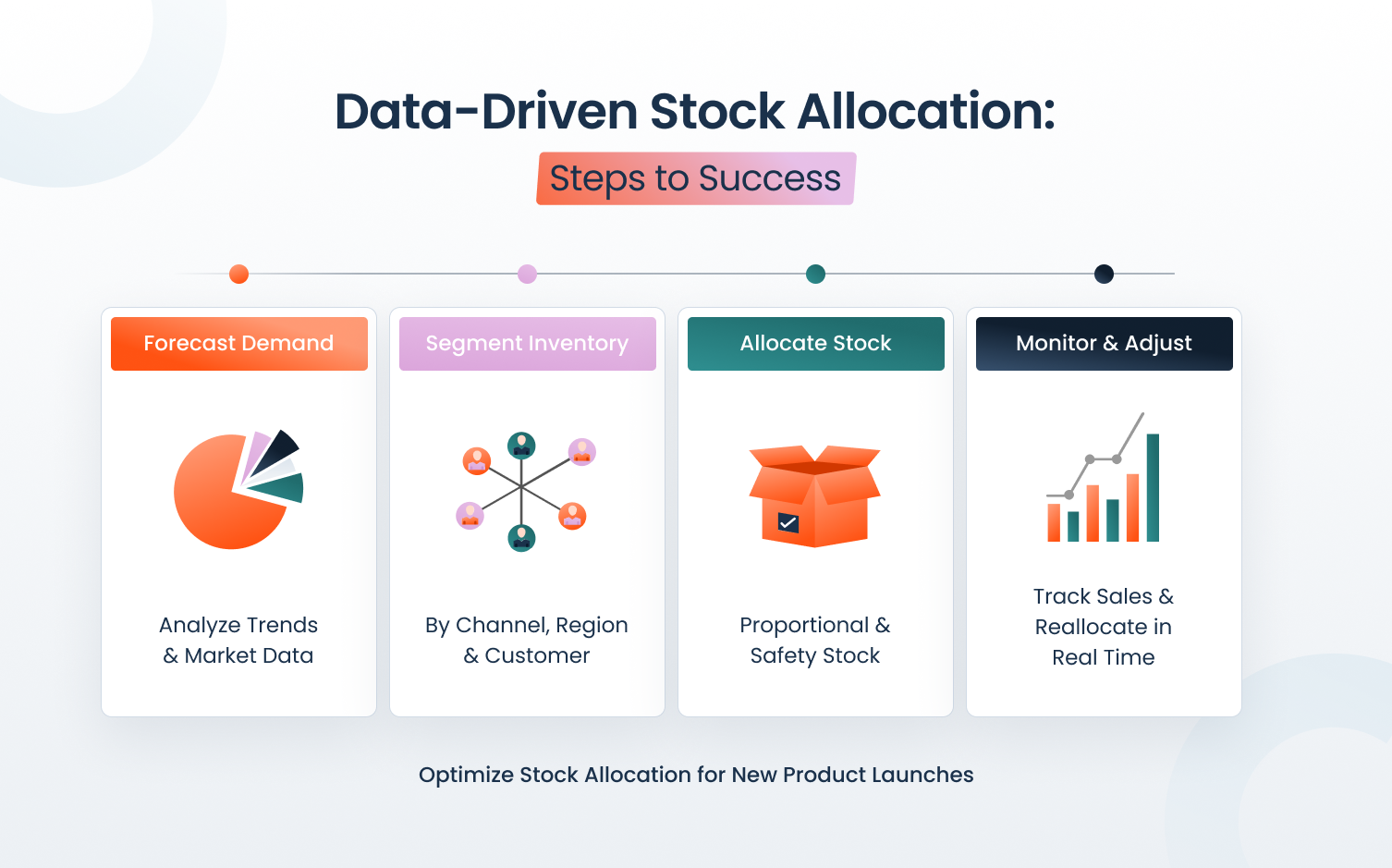

Data-Driven Allocation Methods

- Move beyond guesswork: use demand insights and inventory segments to allocate stock precisely

- Proportional allocation: distribute inventory based on projected demand across channels, regions, or product variants

- Safety stock: add a buffer for unexpected demand spikes or supplier delays

- Buffer stock: reserve extra inventory for high-potential channels or regions during new product launches and adjust allocations as early sales trends emerge.

Fine-Tune Stock Allocation in Real Time

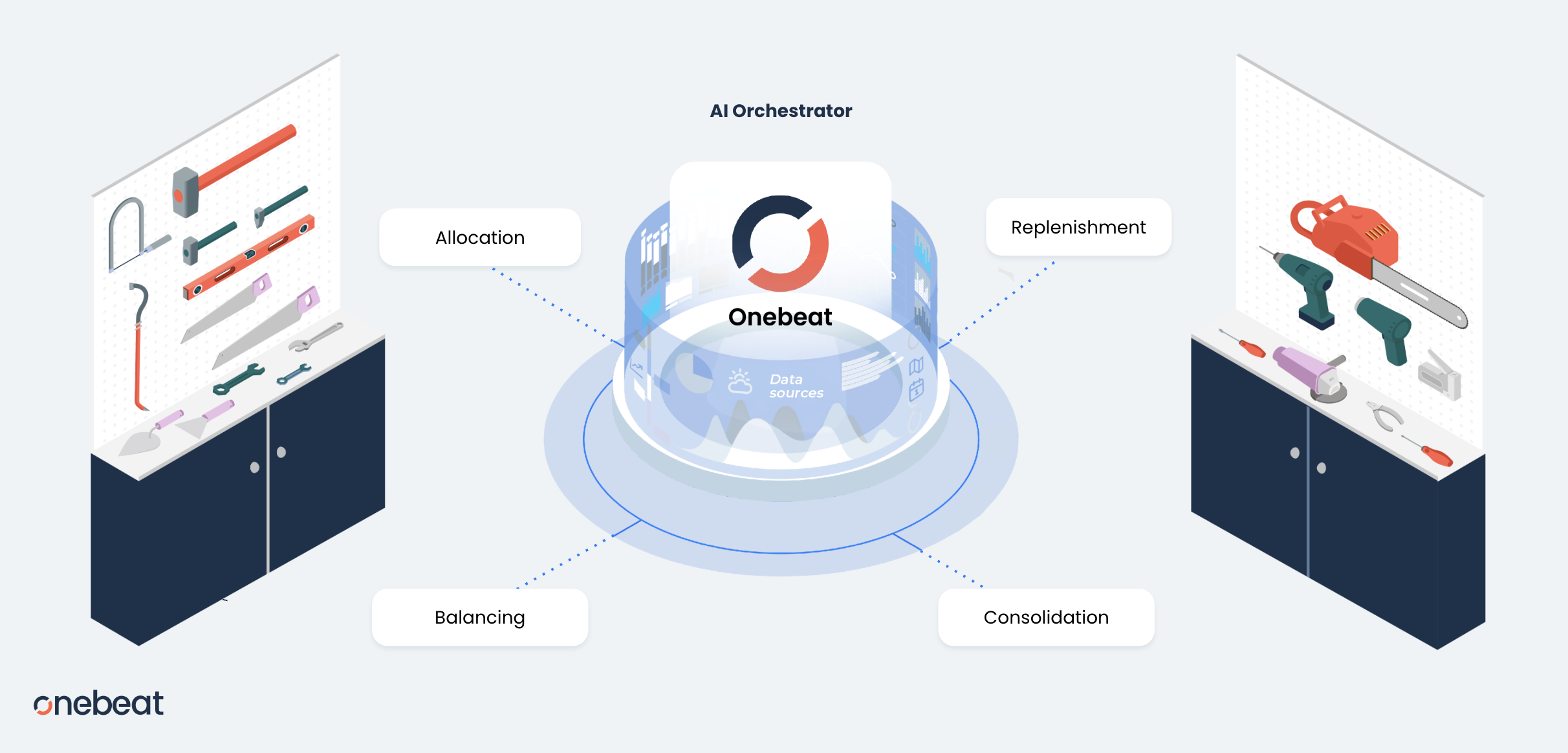

Even the best-laid allocation plans need adjustment once a product hits the market. Real-time monitoring allows you to track sales. By keeping a close eye on high-demand channels or regions, you can shift stock where it’s needed most, respond to unexpected surges, and reduce the risk of overstock. Leveraging technology like Onebeat makes this process even more seamless, providing dashboards that show live inventory, sales velocity, and trends across channels. Staying agile throughout a launch ensures your inventory always aligns with actual demand.

Smart reallocation isn’t just about reacting; it’s about optimizing for maximum revenue. For example, if one online marketplace is outperforming expectations while a brick-and-mortar store is slower, reallocating inventory to the stronger one channel prevents lost sales and reduces carrying costs.

Pro Tip

Combine early sales data with AI forecasting to anticipate surges before they happen. For example, if a product variant is trending on social media, proactively shift stock to high-demand regions.

Ready to Launch with Confidence?

Request A OneBeat DemoFAQs

- How much buffer stock should I keep for a new product launch?

Maintain a centralized buffer to cover unexpected demand spikes or supply delays, and use it to support high-performing channels or regions as early sales trends emerge.

- Can I rely solely on historical data for allocation?

No, historical data should be combined with market research, customer insights, and external factors like seasonality or promotions for more accurate demand forecasting.

- How often should I adjust stock during a launch?

Adjust allocations regularly throughout the launch by monitoring real-time sales performance across channels, regions, and customer segments.

- Is real-time allocation worth the investment?

Real-time allocation helps you respond to demand shifts quickly, prevent stockouts in fast-moving channels, and reduce excess inventory elsewhere.

About the Author

Onebeat co-founder and CEO, Yishai Ashlag, is an economist, author, and globally recognized authority in Theory of Constraints (TOC) methodology. A former partner and founding member of Goldratt Group and post-doctoral fellow at the Wharton School of Business, Ashlag brings academic acumen and decades of experience in management consulting to leading operational excellence and sustainable growth through innovation for Onebeat and retail at large.

Ashlag holds a Ph.D. in Economics from Bar Ilan University and is the author of acclaimed fiction and non-fiction titles on the topic of managing uncertainty, TOC, and more.

Onebeat